The final stretch of the year—driven by the frantic delivery schedules of Christmas and Three Kings’ Day—is the period of maximum pressure and minimum tolerance for error for logistics and e-commerce companies.

At Applivery, we see this cycle repeat annually: during these critical weeks, order volumes can triple or more, severely testing every link in the supply chain, especially the technology that drives the movement of goods.

According to the Zebra Warehousing Vision Study, 87% of decision-makers agree that their operations depend entirely on modernizing their fleet of devices to meet the increasing consumer demand and maintain competitive operational speeds.

Infrastructure overload

The core issue is that your technological infrastructure, which operates comfortably the rest of the year, faces an unsustainable overload during peak season. Any minor failure that would be tolerable in March becomes a costly bottleneck in December.

The difference between a profitable season and a disastrous one lies in the ability of those devices to maintain 100% availability under the immense stress of the holiday campaign.

The cost of reactive management

The most pressing concern for operations leadership isn’t demand, but continuity: the risk that a single hardware glitch or software bug could paralyze the supply chain during the year’s most critical weeks.

The problem? Traditional device management is often reactive. You only learn about an issue after it has already created a bottleneck. VDC Research highlights the severity of this issue: in environments relying on rugged mobile devices, each failure event results in an average of 74 minutes of lost productivity.

In December, you cannot afford 74 minutes of downtime due to a predictable failure like:

-

An operator leaving their station to take a broken scanner to support.

-

An auto-launched OS update slowing down the picking app.

-

A device’s battery unexpectedly dying mid-shift.

Are you managing a fleet of industrial devices? Discover deep-dive strategies to extend hardware lifecycle and secure your supply chain in our free whitepaper.

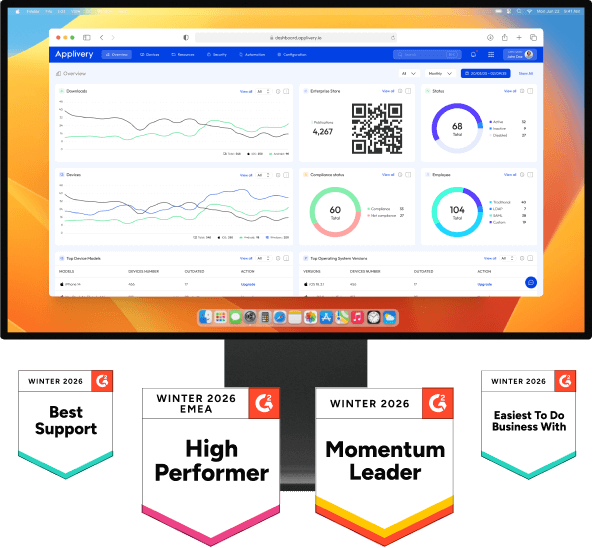

Achieving zero downtime with Applivery

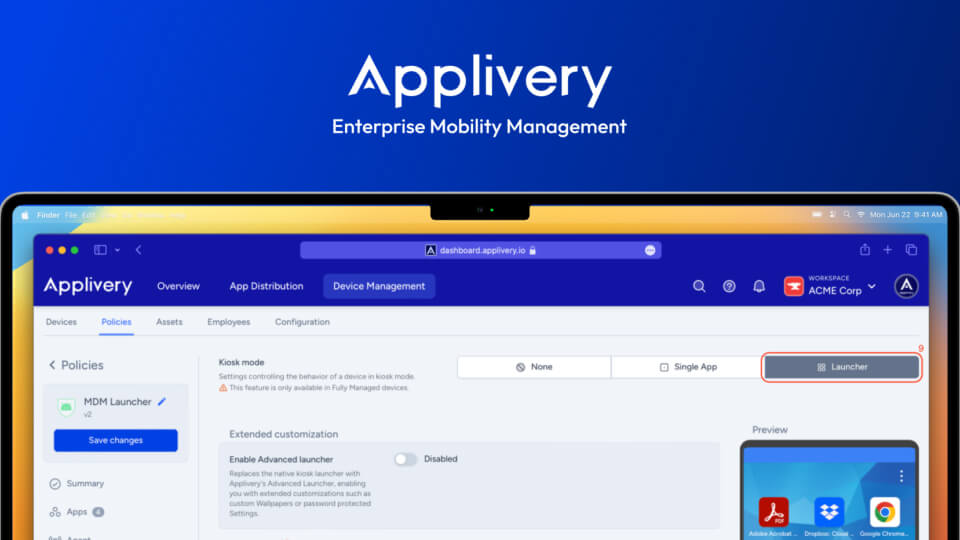

Applivery empowers your logistics operations with a Unified Endpoint Management (UEM/MDM) platform designed specifically to ensure the continuous operation of your rugged devices. This approach transforms your fleet management from a reactive burden into a proactive engine of efficiency and security, guaranteeing that your warehouse never stops.

Proactive performance management

Applivery doesn’t just manage; it anticipates failures:

-

Real-time battery monitoring: set critical thresholds. If a battery’s capacity drops below 85%, Applivery automatically alerts you, allowing supervisors to replace it before the device dies during a crucial shift.

-

Application and OS reporting: get live data on application crashes and memory usage. Identify the failing device or batch before the complaint reaches the support team.

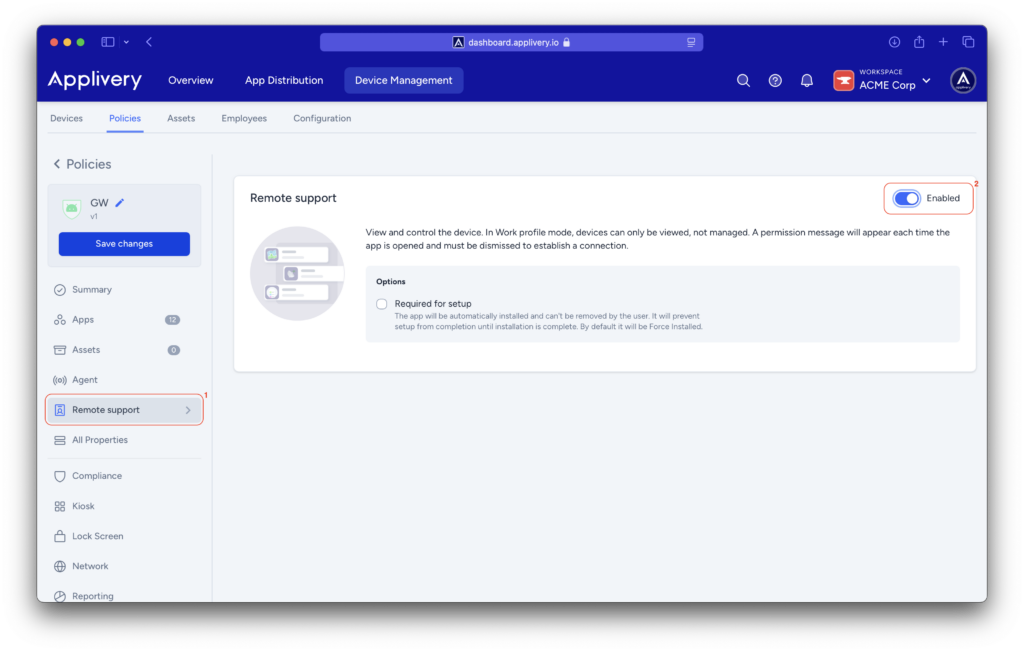

Total control over updates (the freeze)

Operational security is more critical than the latest firmware version in December.

-

Automatic update lockout: use Applivery to pause, defer, and block all OS updates (iOS, Android, Windows) and security patches during peak activity weeks.

-

Pilot group testing: critical updates are first tested on a small, isolated QA group defined in Applivery and only released to the entire fleet after successful validation.

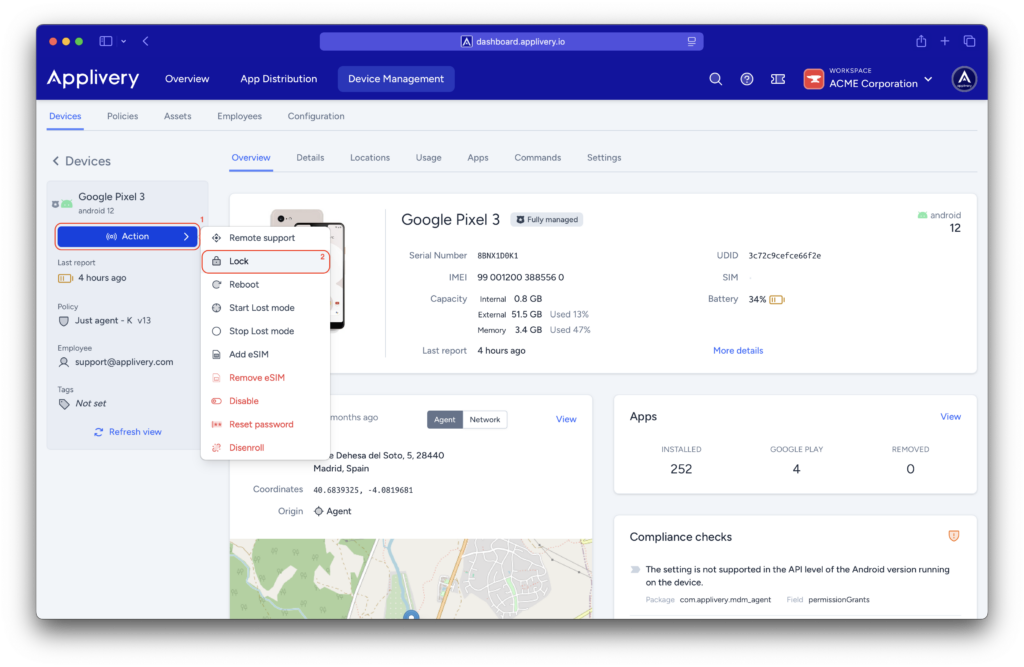

Seamless remote support (remote triage)

Cut the transit time between incident and resolution to zero:

-

Remote control and shadowing: IT technicians can remotely take control of any device on the warehouse floor to diagnose and fix configuration errors without leaving their desk.

- Silent configuration & remediation: push critical setting changes (like Wi-Fi credentials or policy refreshes) in the background without interrupting the operator’s active session, resolving connectivity glitches invisibly.

Why Applivery is your strategic partner for peak season

Applivery’s value for your logistics operation boils down to three strategic pillars:

- Unbreakable reliability: you gain the control to shield your devices against human error and technical failure, ensuring the hardware is always ready.

- Temporary staff efficiency: with the Zero-Touch provisioning feature, new scanners for seasonal staff are ready instantly. We utilize a strict security profile (Kiosk Mode) that restricts usage to only the necessary warehouse apps.

- Operational savings: by preventing just one day of downtime or one major bottleneck in the holidays, the cost of the MDM solution is instantly recouped.

Don’t let the most important season of the year be held hostage by a failing device. Proactive device management is the key to your business’s profitability and reputation during the peak season.

Frequently Asked Questions (FAQ)

How does MDM reduce downtime in warehouses?

MDM platforms like Applivery reduce downtime by allowing IT teams to monitor battery health remotely and fix software issues without waiting for the device to be brought to the helpdesk. Studies show this can save over an hour of productivity per incident.

Can I stop updates during peak season?

Yes, with Applivery you can enforce a "freeze" policy to block OS updates during critical periods like Christmas, preventing unexpected reboots or compatibility issues.

Is it difficult to set up devices for temporary workers?

No. Using Zero-Touch provisioning, you can ship devices directly to the warehouse. When the temporary worker turns it on, it automatically configures itself with the necessary apps and restrictions in minutes.